Setting up a 75mm HDPE Mono Film Plant with a Beam Winder involves several stages, from the installation of equipment to adjusting settings for optimal performance. Here’s a comprehensive guide to help you through the entire process:

1. Pre-Installation Requirements

Before setting up the plant, ensure you have the following:

- Location: A clean and spacious area with proper ventilation.

- Power Supply: Stable 3-phase power supply (usually 400V).

- Water Supply: Adequate cooling water for the extruder.

- Compressed Air: Required for some pneumatic components.

- Materials: HDPE granules (with specific melt flow index, density, and additive compatibility).

- Team: Skilled operators, technicians, and engineers.

2. Equipment Required

- HDPE Mono Film Plant: The core of the plant, used for melting and extruding HDPE resin into film.

- Features: Hopper, barrel, screw (with heating zones), die head.

- Chill Roll Unit: Cools and solidifies the extruded film.

- Features: Steel or rubber-coated rollers, water cooling system.

- Corona Treater: Enhances the surface energy of the film to improve printability and adhesion.

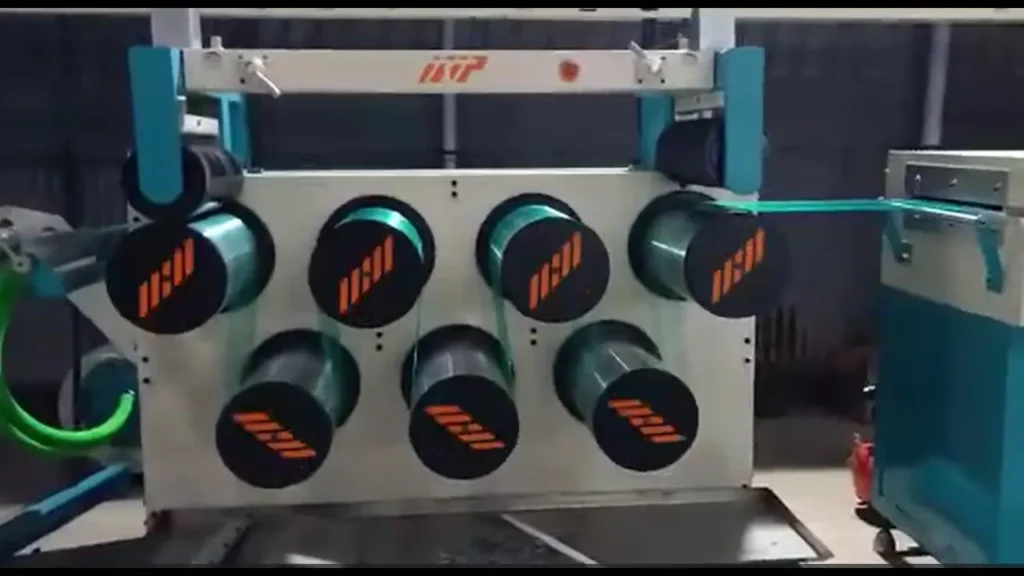

- Beam Winder: Collects the film on large rolls after processing.

- Features: Tension control, speed adjustment, and beam size accommodation.

- Trim Winder/Edge Trimmer: Removes excess material from the edges.

- Control Panel: Centralized system for monitoring and controlling extruder temperature, speed, and winder operations.

- Auxiliary Equipment: Cooling tower, vacuum pumps, conveyors. HDPE Mono Film Plant

3. Installation Process

a) Positioning the Extruder

- Ensure that the extruder is placed on a level surface.

- Align the machine to minimize vibrations during operation.

- Connect the power supply and ensure all electrical connections are secured.

- Attach the cooling system (chill rolls, vacuum systems, and water supply).

b) Mounting the Die Head

- Attach the die head to the extruder outlet, ensuring it’s tightly secured.

- Adjust the gap between the die lips to control film thickness.

c) Chill Roll Setup

- Position the chill roll unit directly after the die head.

- Ensure the rollers are parallel to avoid wrinkling of the film.

- Connect water supply for the cooling system.

d) Corona Treater Assembly

e) Beam Winder Installation

- Set up the beam winder at the final stage of the film process.

- Ensure the tension and winding speed are adjustable.

- Load an empty beam core onto the winder and secure it in place. HDPE Mono Film Plant

4. Calibration and Settings

a) Extruder Settings

- Temperature Zones: Set appropriate temperatures for the extruder, typically ranging between 180°C and 230°C depending on the HDPE grade.

- Screw Speed: Set the screw rotation speed to control the extrusion rate.

b) Die Head Settings

- Adjust the die lips to control the film’s thickness, typically ranging from 20 microns to 100 microns.

c) Chill Roll and Cooling

- Adjust the chill roll speed to synchronize with the extrusion speed.

- Ensure the cooling water is flowing at the correct rate to solidify the film uniformly.

e) Beam Winding

- Set the winding tension to avoid film stretching or sagging.

- Adjust the winding speed in sync with the extruder and chill rolls.

5. Trial Run

a) Start the Extruder

- Feed HDPE granules into the hopper. HDPE Mono Film Plant

- Gradually increase the temperature of the zones and start the screw rotation.

b) Film Extrusion

- Once the HDPE is fully melted, film will begin to extrude from the die head.

- Guide the film onto the chill rolls, ensuring it cools uniformly.

c) Corona Treatment and Winding

- After the film passes through the chill rolls, guide it through the corona treater.

- From the corona treater, lead the film to the beam winder. HDPE Mono Film Plant

6. Fine-Tuning and Adjustments

- Thickness Control: Adjust the die lips or screw speed to get the desired film thickness.

- Winding Tension: Ensure the beam winder is not overstretching the film by fine-tuning the tension control.

- Cooling Efficiency: Monitor the cooling system to ensure the film is adequately solidified before it reaches the winder.

7. Maintenance Tips

- Regularly clean the die head to avoid buildup of material.

- Inspect the chill rolls for any wear or contamination that could affect the film quality.

- Lubricate moving parts (like the beam winder and extruder screw) as per the manufacturer’s instructions.

- Regularly check the electrical connections and ensure all components are functioning properly.

8. Safety Precautions

- Ensure operators are trained in handling hot surfaces and machinery.

- Use appropriate personal protective equipment (PPE), such as gloves and eye protection.

- Have emergency power shut-off systems in place.

This guide covers the key steps for setting up a 75mm HDPE Mono Plant with a Beam Winder. Fine-tuning the process based on your plant’s specific requirements and material grade is essential to achieving high-quality film production.

Full Setup Guide for 75mm HDPE Mono Film Plant

HDPE Mono Film Plant, HDPE Mono Film Plant, HDPE Mono Film Plant